So ive been playing with a couple of calculators to do my plumbing on my 60g cube.

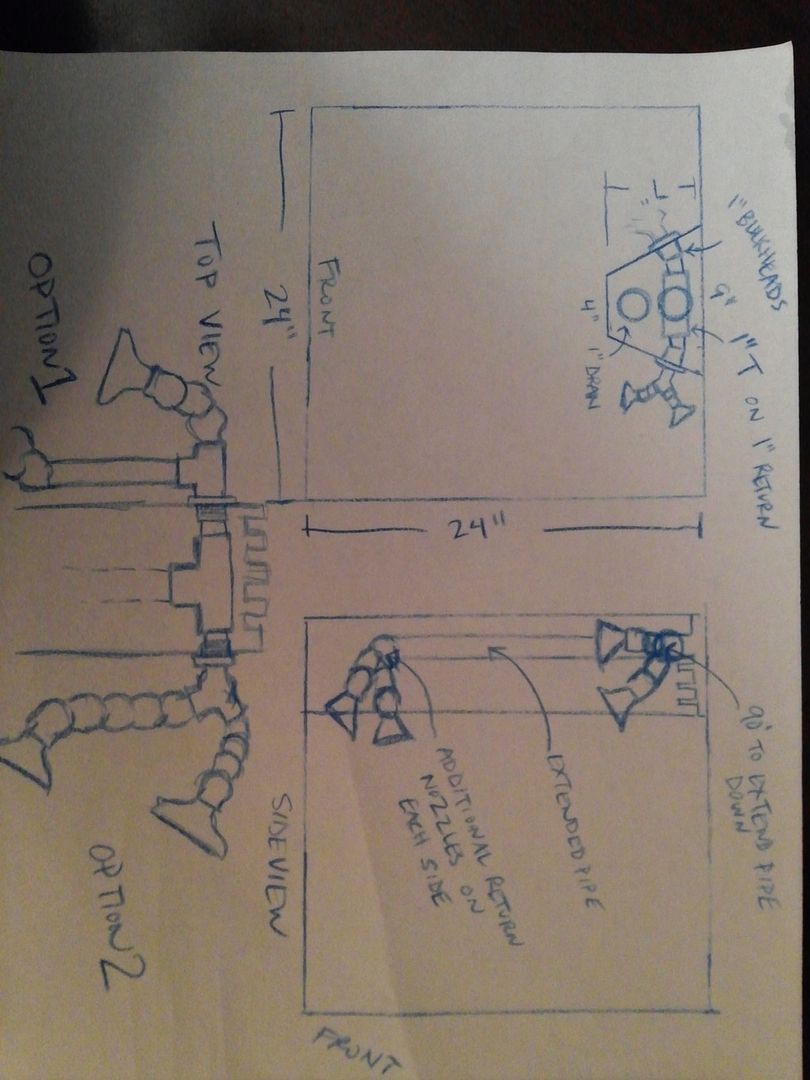

-I will install a 24" tall x 9" long x 4" deep overflow. (Sizes are give/take an inch) with 1" drain pipe. The pipe should give me about 600gph and since its running the height of the tank i dont see any restrictions on gph.

-I will have 3/4" return line from sump. So i will use the headloss calcultor to figure out which pump i can use depending on all my fittings.

So if i have 600gph drain, is it safe to say that i can get a pump that pushes a little over 600gallons and use my ball valve to dial it back a little.....or will getting a pump that pushes a little less be better so that i wont restrict the pump and not worry about going above the capacity my overflow can handle.

I know i will have to make sure my sump is not having too much flow either.

Any advice is appreciated. Also, if im missing anything please let me know

Reply With Quote

Reply With Quote